How to find the best one component epoxy adhesive for electronics PCB underfill

7Newswire

15 Dec 2022, 11:08 GMT+10

Epoxy adhesives are versatile and easy to use, making them ideal for a variety of applications. In this blog post, we will be focusing on one component of epoxy adhesives. One component epoxy adhesives are perfect for bonding dissimilar materials and have high shear and peel strength. They can be used in a wide range of industries, including automotive, aerospace, electronics, and more. If you're looking for an adhesive that can provide a strong bond and is resistant to harsh environments, then one-component epoxy adhesives are the way to go.

As strong as some two-part epoxy adhesives, one-component epoxy adhesives cure at room temperature and do not require mixing before use. They typically have a longer working time than two-part epoxies, giving you more time to align and position your workpiece. One-component epoxy adhesives are also often more forgiving than their two-part counterparts, making them ideal for less experienced users or for situations where precise mixing is difficult.

- Types of One-Component Epoxy Adhesives

One component epoxy adhesives are available in a variety of formulations to suit different bonding needs. The three main types of one-component epoxy adhesives are:

- Structural adhesives: These adhesives are designed for bonds that need to withstand high stresses. They have excellent strength and durability, making them ideal for structural applications.

- Assembly adhesives: These adhesives are designed for bonding together assemblies of parts. They have good strength and durability, and can be used on a variety of materials.

- Finishing adhesives: These adhesives are designed for cosmetic applications where a strong bond is not required. They have good aesthetics and can be used on a variety of materials.

What are One Component Epoxy Adhesives?

One component epoxy adhesives are epoxy-based adhesives that require only one component to cure. This makes them ideal for bonding dissimilar materials, as they can be applied directly to the surface without the need for a separate activator or hardener. They also have excellent resistance to temperature and chemicals, making them ideal for use in harsh environments. One component epoxy adhesives are available in a variety of formulations to suit different applications and can be applied using various methods including brush, roller, or spray.

The Different Types of One Component Epoxy Adhesives

There are many different types of one component epoxy adhesives, each with their own unique set of properties. Here is a brief overview of the most common types:

- Structural adhesives are designed for bonding high strength materials such as metals and composites. They typically have a very strong bond strength and can resist high temperatures and stress.

- Instant adhesives are designed for quick bonding of materials such as plastics and rubbers. They have a fast setting time and provide a strong bond.

- Low temperature adhesives are designed for bonding materials that are sensitive to heat, such as electronics. They have a low cure temperature and can be used in difficult-to-reach areas.

- High temperature adhesives are designed for applications where high temperatures are encountered, such as in engine compartments. They can withstand extreme temperatures and provide a strong bond.

you can pay a visit to->https://www.deepmaterialcn.com/

Pros and Cons of One Component Epoxy Adhesives

One Component Epoxy Adhesives, also known as OCA, offer many benefits over traditional adhesives. They are typically stronger, more durable, and easier to apply. However, there are some drawbacks to using OCA as well.

PROS:

-Stronger than traditional adhesives

-More durable

-Easier to apply

-Can be used on a variety of surfaces

CONS:

-May yellow over time

-require special tools and equipment for application

What are the Best Uses for One Component Epoxy Adhesives?

One-component epoxy adhesives are ideal for repairing damaged surfaces, bonding dissimilar materials, and creating a waterproof seal. They can be used on a variety of surfaces, including metal, glass, wood, and plastic. One-component epoxy adhesives are available in a variety of formulations to meet different needs.

How to Apply One Component Epoxy Adhesives

If you're looking for a reliable and long-lasting adhesive, then one component epoxy adhesives are a great option. They can be used on a variety of materials, including metal, glass, and plastics, and they provide a strong bond that can withstand high temperatures and harsh environments.

Applying one-component epoxy adhesives is relatively simple, but there are a few things to keep in mind to ensure the best results. First, be sure to clean both surfaces that will be bonded together with the adhesive. Any dirt, grease, or other contaminants will weaken the bond and could cause it to fail.

Next, roughen up the surfaces to create more surface area for the adhesive to grip onto. You can do this with sandpaper or a wire brush. Once the surfaces are prepared, mix the adhesive according to the manufacturer's instructions.

Then apply the adhesive to one of the surfaces using a brush or roller. Be sure to spread it evenly and smoothly over the entire surface. Immediately place the other surface on top of the adhesive and press it down firmly. Use clamps or weights to hold everything in place while the adhesive dries.

Allow the adhesive to cure for at least 24 hours before subjecting it to any stress or strain. Once it's fully cured, your bond will be incredibly strong and long-lasting!

Conclusion

One component epoxy adhesives are a great option for bonding metal, glass, and plastic. They are easy to use and provide a strong bond that can withstand high temperatures. While they are more expensive than other types of adhesives, their strength and durability make them worth the investment. Share

Share

Tweet

Tweet

Share

Share

Flip

Flip

Email

Email

Watch latest videos

Subscribe and Follow

Get a daily dose of London Mercury news through our daily email, its complimentary and keeps you fully up to date with world and business news as well.

News RELEASES

Publish news of your business, community or sports group, personnel appointments, major event and more by submitting a news release to London Mercury.

More InformationUK Editorials

SectionNurse Admits Amputating Man's Leg Without Permission UK Crime

Nurse Admits Amputating Man's Leg Without Permission UK Crime

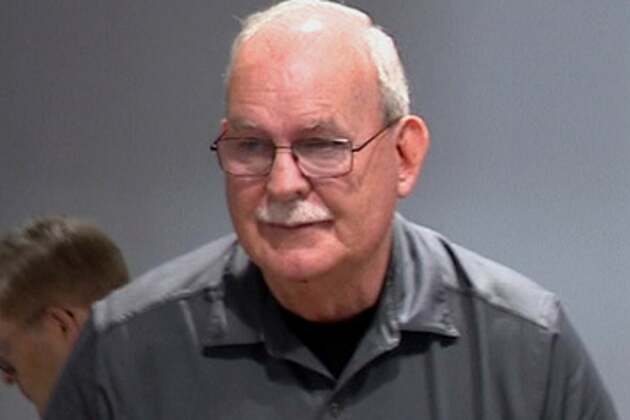

North Carolina Sheriff Retires Amid Sexual Misconduct Charges Latest News

North Carolina Sheriff Retires Amid Sexual Misconduct Charges Latest News

Detroit-Area McDonald's Employee Kills Co-Worker After Argument Latest News

Detroit-Area McDonald's Employee Kills Co-Worker After Argument Latest News

Ex-NBA Player Ben McLemore Sentenced To Prison For Rape Latest News

Ex-NBA Player Ben McLemore Sentenced To Prison For Rape Latest News

Shifting payment landscape- what a digital euro will bring

Shifting payment landscape- what a digital euro will bring

Business

SectionEx-UK PM Sunak takes advisory role at Goldman Sachs

NEW YORK CITY, New York: Former British prime minister Rishi Sunak will return to Goldman Sachs in an advisory role, the Wall Street...

Gold ETF inflows hit 5-year high as tariffs drive safe-haven bets

LONDON, U.K.: Physically backed gold exchange-traded funds recorded their most significant semi-annual inflow since the first half...

PwC: Copper shortages may disrupt 32 percent of chip output by 2035

AMSTERDAM, Netherlands: Some 32 percent of global semiconductor production could face climate change-related copper supply disruptions...

U.S. stocks recover after Trump-tariffs-induced slump

NEW YORK, New York - U.S. stocks rebounded Tuesday with all the major indices gaining ground. Markets in the UK, Europe and Canada...

Stocks slide as Trump unveils 25% tariffs on Japan, S. Korea

NEW YORK CITY, New York: Financial markets kicked off the week on a cautious note as President Donald Trump rolled out a fresh round...

BRICS issues rebuke on trade and Iran, avoids direct US criticism

RIO DE JANEIRO, Brazil: At a two-day summit over the weekend, the BRICS bloc of emerging economies issued a joint declaration condemning...